Look to cow monitoring tools,

not outside, for heat stress indicators

By Haim Fleminger

Are high summer temperatures taking a toll on your herd? Summer creates unique herd management challenges. Heat stress is costly. It is calculated to cost U.S. dairy farms approximately $900 million annually1 so the return on investment on a heat abatement solution has the potential to be quite substantial. Unfortunately, many of these solutions have one glaring problem.

Managing heat stress is challenging because it cannot be easily measured. If you ask 10 different dairies, “What temperature do your cows start to be affected by heat stress?” you likely will get 10 different answers.

All the answers will be from the point of view of individual dairy personnel — observations, temperature, Temperature Humidity Index (THI) or simply their “gut feeling” will be what they use to explain the starting point of cows affected by heat stress.

As you ask the dairies how they determine when to turn on fans and sprinklers/soakers, you again will get 10 different answers. Some are determined by temperature, some by time of day and others by when they typically turn them on.

Multiple well-designed heat abatement solutions are available. Some are simple, and some are very sophisticated. However, all heat abatement systems suffer from one main drawback — they are operated based on external conditions, typically temperature and humidity, and not actual cow behavior.

Ask the cows

We argue that there is only one reliable source of information about the effectiveness of these systems — the actual cows.

Dairy producers don’t have to wait until hot weather to gain insight into cows’ perception of the problem. SenseHub Dairy® technology can spot cows showing heat stress behaviors, even before the THI rises above commonly accepted thresholds for heat stress.

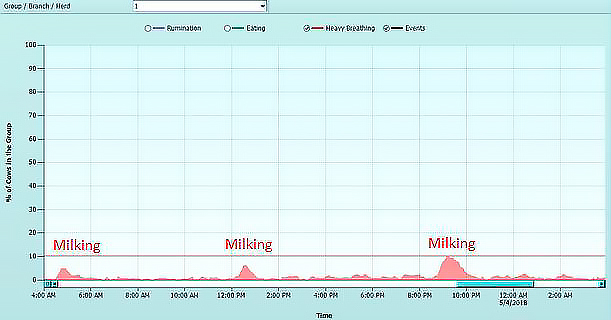

For example, see the graph below, collected from a Northeast U.S. herd on May 4, 2018, using SenseHub® Dairy technology. That day, the THI was 66, below the commonly accepted THI threshold of 68.

Figure 1. Percent of cows panting in pen number 1 over 24-hour period.

Even though only a small percentage of the group is panting, this information provides an early warning about areas where heat abatement is not optimal. Clearly, conditions in the holding pen and in the milking parlor are not working for the cows.

This information can serve as the basis for further investigation of the specific causes of the problem and possible solutions. Immediate cow feedback from technology like SenseHub Dairy enables confidence to try new heat abatement strategies and select the most effective course of action to keep cows comfortable in hot months.

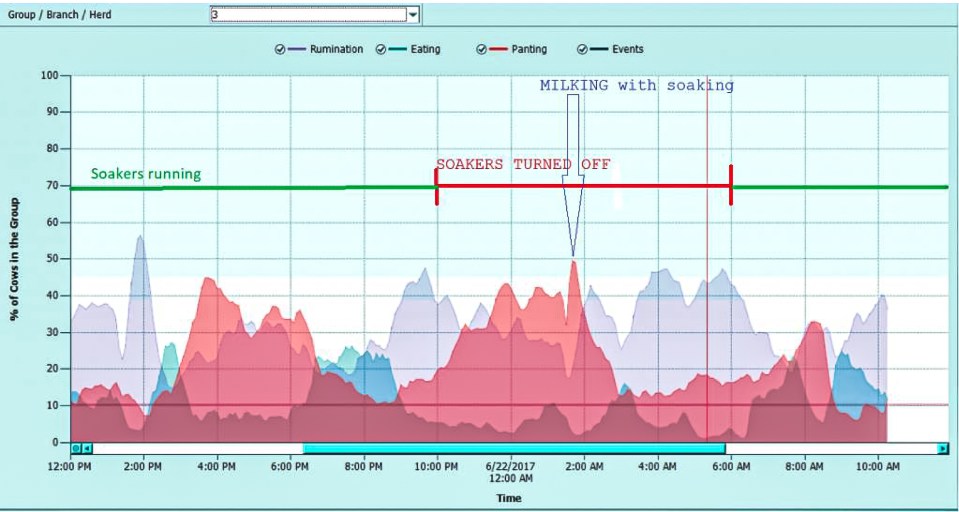

The graphs below outline exactly how long a pen of cows has been under heat stress and what time of day it began. It is common for a SenseHub Dairy user to claim they were close to knowing what the cows were feeling. But in the example below, we see that the assumption that it is cooler at night, so the soakers can be turned off for about eight hours. The cows clearly don’t think the same.

Figure 2. Percentage of cows panting, ruminating, eating during periods of soakers running or not.

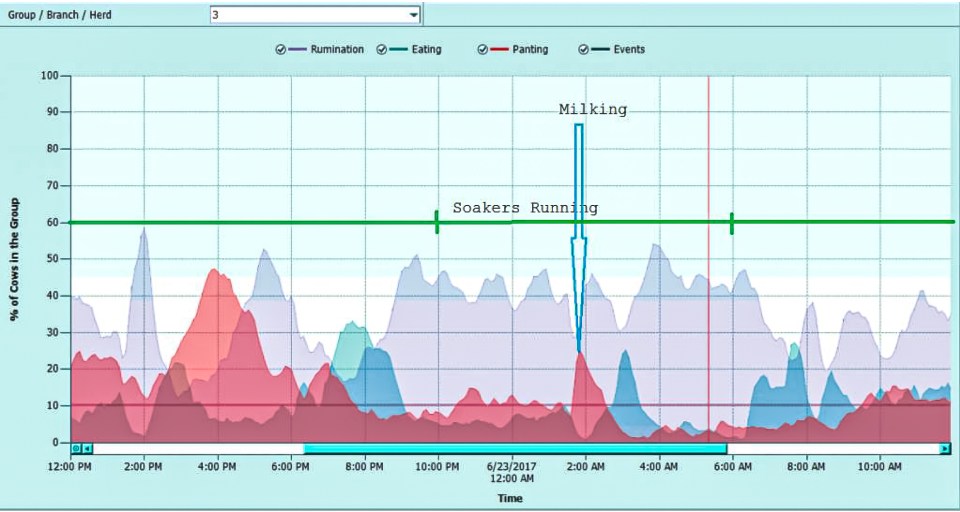

The next day the soakers run throughout the night, the temperature is approximately the same, and the cows have a chance to recover from the heat of the day.

Figure 3. Percentage of cows panting, ruminating, eating while soakers ran all night.

Unarguably, heat abatement is an investment. But previously, those dollars were spent based on the caregivers best guess of cow comfort. With SenseHub Dairy, dairy managers can be more confident in heat abatement decisions.

Disclaimer

SenseHub Dairy is not intended to diagnose, treat, cure or prevent any disease in animals. For the diagnosis, treatment, cure or prevention of disease in animals, you should consult your veterinarian. The accuracy of the data collected and presented through this product is not intended to match that of medical devices or scientific measurement devices.

Resources

- St-Pierre, N., Cobanov, B., & Schnitkey, G. Economic Losses from Heat Stress by US Livestock Industries. J. Dairy Sci. 2023. 86, E52–E77.

https://doi.org/10.3168/jds.s0022-0302(03)74040-5.

Find more content for your dairy operation.

About the author

Haim Fleminger

Key Account Manager – Dairy Monitoring

Merck Animal Health